World-leading services in process development, optimisation, and heterogeneous catalysis

Transparency and efficiency in delivering excellence

We work with a major multinational clientele in the chemicals and energy industries as well as leading research organisations. We value your data – all projects are performed under strict confidentiality.

International Customer Base

Over the last years, we worked for multiple customers including several major pharma and fine chemicals companies, petrochemical, aerospace, and research organisation.

The logos show only a small fraction of customers because most of the work is performed under the strictest confidentiality.

The expertise of Stoli in coatings helped us to develop new generation catalysts to improve one of our manufacturing processes.

Stoli scaled-up catalyst from grams to kilograms allowing us to complete a feasibility project.

Stoli Chem have performed a feasibility study and evaluated batch to continuous conversion for our process

Services: Catalysis

Catalyst Research

No task is too big or too small. We develop catalysts for fine chemical, oil & gas, and polymer industries.

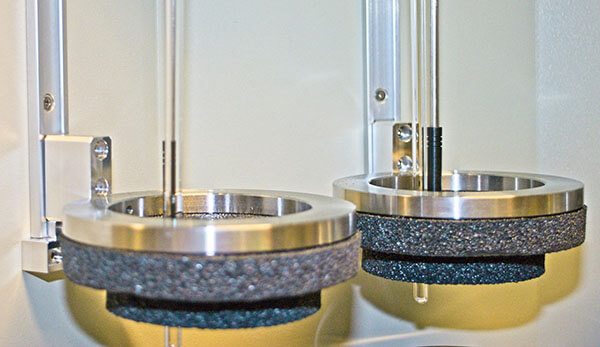

Stoli Catalysts’ modular reactors combined with our rapid-testing facilities allow probing deeper into catalysts for a higher efficiency and selectivity. We create low-loading precious metal catalysts for high efficiency with excellent cost savings! Ask us about your new idea and discuss feasibility, piloting or scale-up projects.

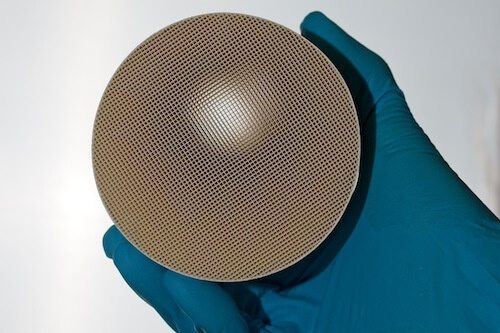

Catalyst Coating

Catalysis in thin coatings eliminates heat and mass transfer limitations, creates new opportunities for intensified reactions and enhances product selectivity.

We are experts in catalyst coatings – conventional (sol-gel coating, grafting, evaporation) as well as proprietary (2 pending patents) techniques. Our catalyst-coated reactor tubes create enhanced productivity in lab-scale hydrogenation. Talk to us about your needs for catalytic coatings.

Kilogram-scale Catalyst Manufacture

Stoli has experience in lab to pilot-scale catalyst manufacture for fast execution of feasibility studies. We have developed and manufactured kilo-scale precious metal catalysts, bimetallic materials, zeolites and others. Talk to us about scaling up your idea.

Case studies: Catalysis

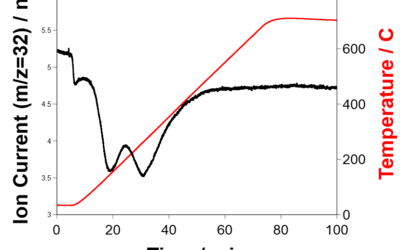

Temperature Programmed Oxidation of Cu Catalyst

We studied a Cu-based catalyst and correlated oxidation state of Cu with catalytic performance

Catalyst for fuel cell applications

We have developed a monolith-based fuel cell catalyst for sustainable remote energy generation.

Characterisation-directed kilo catalyst scale-up

We manufactured 10 kg catalyst using characterisation to validate the scale-up procedure from lab to manufacturing processes.

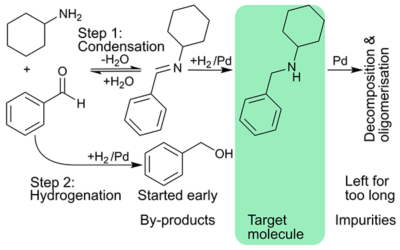

Cascading imine formation and hydrogenation

Stoli cascaded imine formation and hydrogenation; intensified process to maximise rate, and catalyst utilisation.

Developing a catalyst for a highly explosive reaction

After 100 long-term runs and building a bespoke reactor system to manage safety risks, we developed a stable catalyst with months at least 2 month lifetime.

Process intensification in hydrogenation

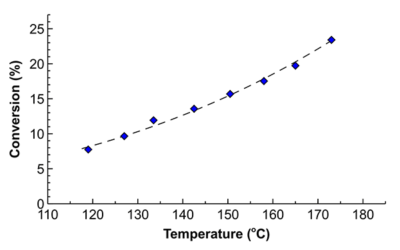

Short residence time and high temperature – an impossible combination for batch – allowed increasing specific reaction rates 8-fold in flow with the same product quality.

Services: Characterisation

Active Site Studies

We have a range of tools at our lab to help you with your characterisation requirements. The techniques we offer include but not limited to:

– Temperature-programmed oxidation (TPO) with mass-spectrometry detection

– Temperature-programmed reduction (TPR) with mass-spectrometry detection

– Adsorption and temperature-programmed desorption of ammonia with mass-spectrometry detection

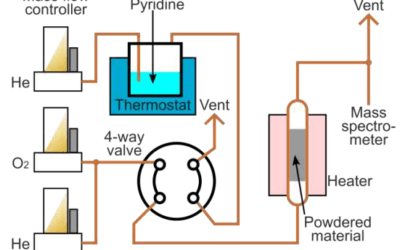

– Adsorption and temperature-programmed desorption of pyridine with mass-spectrometry detection

– Chemisorption of carbon monoxide (CO) with mass-spectrometry detection

– Chemisorption of hydrogen (H2) with mass-spectrometry detection

– Temperature-programmed desorption and desorption of probe molecules

– Surface area and porosity (BET surface area, BJH pore volume, pore volume distribution)

– Gas and HPLC chromatography (GC, HPLC)

– UV absorption and photoluminescence

Advanced Surface Analysis

Working closely with the several universities, we provide advanced analytical techniques.

Advantages of choosing us: we suggest the studies required to suit your needs, provide full interpretation, and rapid turnaround.

Talk to us to discuss your problem and the most efficient way to solve it.

X-Ray techniques including powder X-ray diffraction or single-crystal X-ray diffraction

Transmission electron microscopy (TEM)

High-resolution transmission electron microscopy (HRTEM)

Scanning electron microscopy including energy dispersive spectroscopy (SEM)

Elemental mapping and elemental analysis with X-ray fluorescence (XRF)

Solution phase nuclear magnetic resonance (NMR)

Infrared spectroscopy (FTIR)

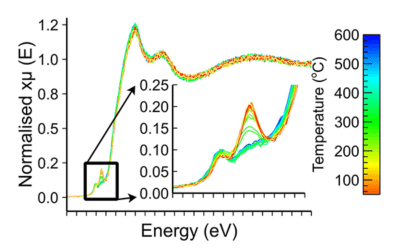

Bespoke Characterisation

We love a challenge! We are willing to provide an innovative solution to meet your demands. We offer bespoke characterisation facilities that require building dedicated testing systems. These include thermal conductivity and capacity for materials, high-temperature catalyst attrition studies. We have recently completed challenging in-situ X-ray absorption (XAS) studies, over a large temperature range, at the Diamond Light source in Harwell.

Case studies: Characterisation

Temperature Programmed Oxidation of Cu Catalyst

We studied a Cu-based catalyst and correlated oxidation state of Cu with catalytic performance

Pyridine Chemisorption analysis service for characterisation of acid sites

A case study on the pyridine chemisorption services we perform which determine the number of the corresponding acid sites in a material.

X-Ray Absorption Spectroscopy (XAS)

We completed in situ synchrotron studies of a customer’s catalyst at the Diamond Light Source Facility.

Characterisation-directed kilo catalyst scale-up

We manufactured 10 kg catalyst using characterisation to validate the scale-up procedure from lab to manufacturing processes.

Services: Proof of concept

System Design, Modelling and Prototyping

With in-house rapid prototyping and 3D printing facilities, we can design and produce quality prototypes and models for testing. We are experts in process automation, modelling and computer aided design to help you at every stage of process or product development. Talk to us to streamline your route to market.

Proof of Concept Projects

Do you have an idea but are not sure if it works or is scalable? We translate ideas into reality whether you are developing a new chemical process, improving the heat exchange rate, scrubbing pollutants, or developing equipment for outer space exploration. We specialise in rapid prototyping and iteration, working closely with our customers.

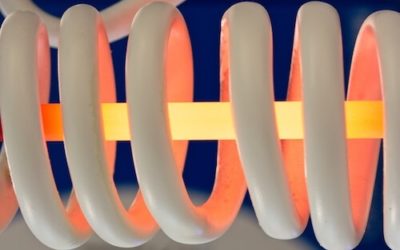

Advanced Reaction Energy

We explore alternative energy sources for processes and develop radiofrequency (induction) and microwave heating systems to target the energy to the place it is required. We also work with non-thermal plasma processing to address the needs for more efficient and distributed processing systems.

Case studies: Proof of concept

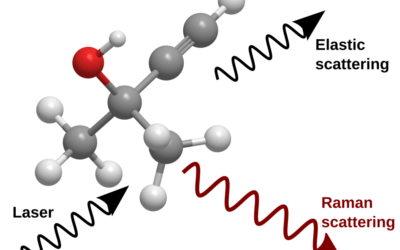

Raman Spectroscopy for online analysis: effect of gases, solids, laser power, aquisition time, signal/noise and more….

We investigated Raman spectroscopy for online analysis by monitoring hydrogenation reactions through relative peak intensities, subsequently, determine the concentration of components.

Characterisation-directed kilo catalyst scale-up

We manufactured 10 kg catalyst using characterisation to validate the scale-up procedure from lab to manufacturing processes.

Developing a catalyst for a highly explosive reaction

After 100 long-term runs and building a bespoke reactor system to manage safety risks, we developed a stable catalyst with months at least 2 month lifetime.

Process intensification in hydrogenation

Short residence time and high temperature – an impossible combination for batch – allowed increasing specific reaction rates 8-fold in flow with the same product quality.