Continuous chemical reactors from lab to production

Our innovative chemical rectors enable seamless scalability and reliable manufacture of chemicals from pharma to commodities; from grams to kilo-tonnes.

Multipurpose continuous reactors for faster, cheaper, and safer chemistry.

We offer services in heterogeneous catalysis, catalyst coating, characterisation, and process development.

IEEA grant for sustainable chemical production

Stoli Chem awarded a grant to scale up continuous flow manufacturing

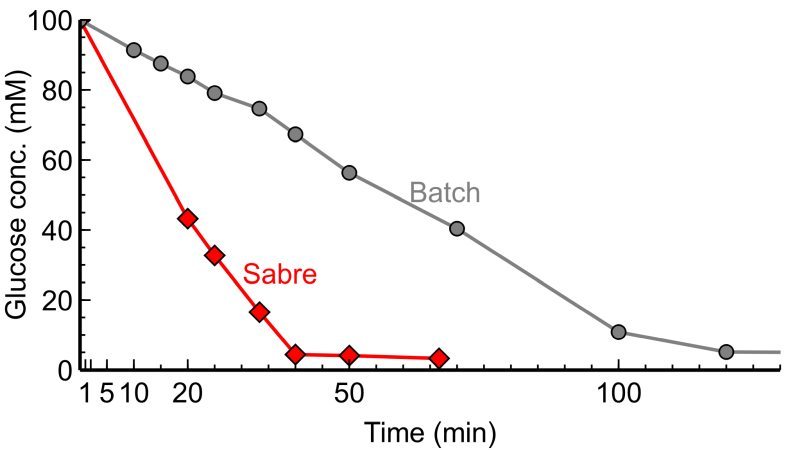

Improvement of enzymatic oxidation in the continuous Scalable Agitated Baffle Reactor (SABRe) system

Case study on enzymatic oxidation by Prof John Woodley

Flow Chem India 2023

We will be presenting at Flow Chemistry India 2023!

Expertise & Excellence

Established in 2016 as a Warwick University spinout, we capitalise on our extensive expertise in heterogeneous catalysis and continuous process chemistry.

Our excellence has been recognised by receiving numerous awards and highly competitive grants such as a £500k Innovate UK grant, participation in the Royal Society of Chemistry Emerging Technologies competition and the award of a Royal Academy of Engineering Enterprise Fellowship, KTN accelerator, and a €1.2M Horizon 2020 SME Instrument grant #848926 to provide sustainable manufacturing of chemicals at a lower manufacturing costs.

International Customer Base

Over the last years, we worked for multiple customers including several major pharma and fine chemicals companies, petrochemical, aerospace, and research organisation.

The logos show only a small fraction of customers because most of the work is performed under the strictest confidentiality.

International Customer Base

Over the last years, we worked for multiple customers including several major pharma and fine chemicals companies, petrochemical, aerospace, and research organisation.

The logos show only a small fraction of customers because most of the work is performed under the strictest confidentiality.

NEW! Scalable Agitated Baffle Reactor (SABRe)

Best in class mixing performance

For rapid scalability and handling complex processes

Our reactor improves and simplifies a series of stirred tanks providing all the benefits without their complexities. You already know about batch hydrodynamics – these all apply to our reactor.

Many impellers in small chambers maximise heat & mass transfer for excellent reaction control, high yield, simple reaction cascades and expanded chemistries (exothermic, labile, explosive). The reactor is configurable in minutes for various impellers or reactions. You save on materials, overheads, and labour.

Batch reactors limit your chemistry scope and yield

Slow heat & mass transfer requires cryogenics, limits throughput, and creates impurities

Discontinuous processes result in large inventories, labour and overhead costs

Yet, batch is simple and versatile

Our reactor combines benefits of both flow and batch

Batch reactors limit your chemistry scope and yield

Slow heat & mass transfer requires cryogenics, limits throughput, and creates impurities

Discontinuous processes result in large inventories, labour and overhead costs

Yet, batch is simple and versatile