Scalable Agitated Baffle Reactor

Combines the benefits of batch and flow:

Flexibility of batch. SABRe is multipurpose, and scalable. All the batch engineering and applies.

Performance of flow. SABRe heat and mass transfer is close to that of tubular and chip reactors.

Result: higher product quality, faster development, higher throughput.

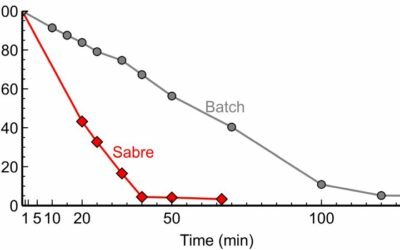

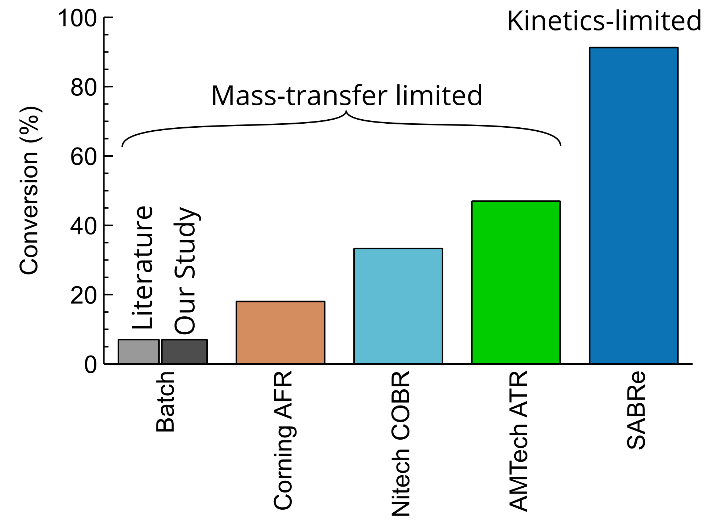

Best in class performance

Proven in the liquid-liquid enzymatic esterification comparing batch, chip, and other agitated continuous reactors!

To move rapidly from laboratory, to pilot, to production scale.

- Rapid scalability

- Speeding-up complex and exothermic process

- Process intensification – high throughput at low cost

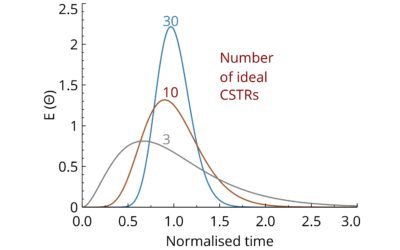

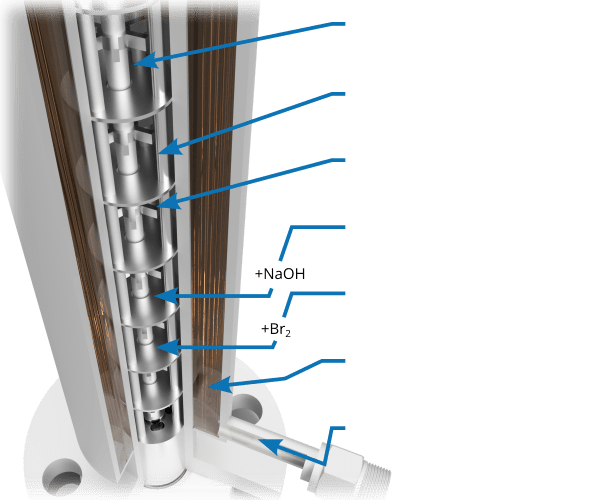

SABRe: series of continuous stirred tanks (CSTRs) reimagined: simple, multi-purpose, scalable

Each chamber is a stirred tank

Mixing independent on flow rates

Reagents could be added or removed

That enables simple & efficient reaction cascades

Precise contol of residence time

Several temperature zones

Rapid heat transfer with standard circulators

Modular design for many applications

Designed to work as a drop in replacement for jacketed batch reactors, SABRe is compatible with major pumps, chillers, heaters and overhead stirrers. You don’t have to invest in a new suite of equipment to explore continuous manufacture.

One pressure vessel provides

- several reactor volumes

- various impellers

- various inlet/outlet points

- various number of chambers

- different baffle geometry

… all with a removable insert

Rapid scale-up of precision chemical manufacturing

SABRe provides unrivalled reaction control, even at long residence times and large scale.

Mixing independent on pumping rates enables consistent, controllable, and predictable mass transfer performance.

Several jacket options enable high heat transfer rates for handling hazardous and exothermic reactions.

The SABRe system is offered in 3 standard sizes for lab, pilot and production scale, allowing the user a clear route to scale up without sacrificing yield, purity or energy efficiency.

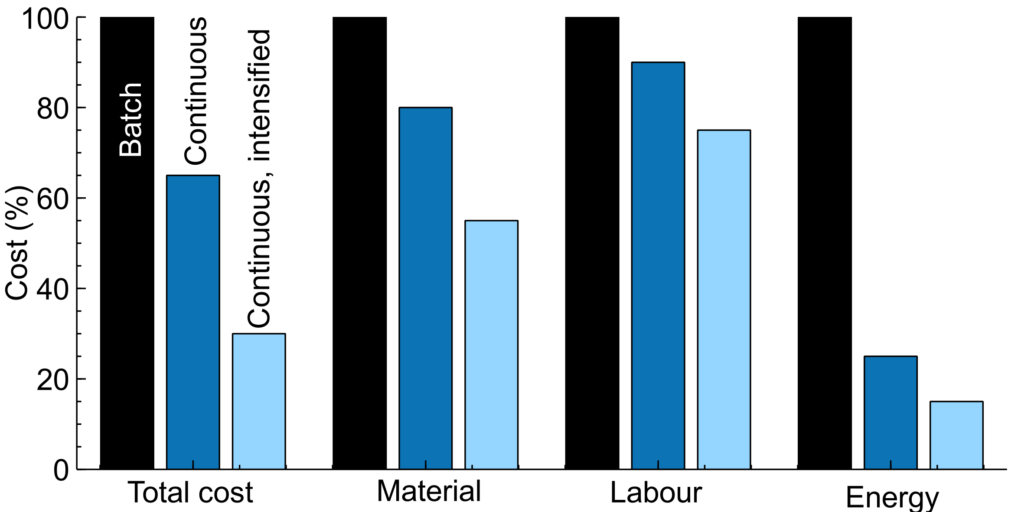

Saves materials, energy and labour costs

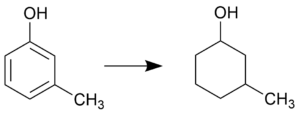

Example process -aromatic hydrogenation of cresol

Savings are proven independently

(similar reactor concept): Machefer, S., Falk, L., & de Panthou, F. (2013). DOI: 10.1016/j.cep.2012.06.005

Predictable performance fully characterised

Improvement of enzymatic oxidation in the continuous Scalable Agitated Baffle Reactor (SABRe) system

Case study on enzymatic oxidation by Prof John Woodley

Steven’s oxidation with Vapourtec

1.4 kg/day multiphase oxidation obtained integrating SABRe system with Vapourtec’s R-Series

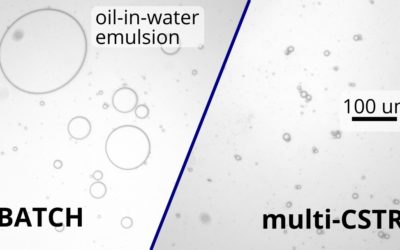

Consistent oil-in-water emulsions in continuous flow

Using a continuous multi-CSTR system allowed us to make droplets 2.5 times more uniform compared to a batch reactor

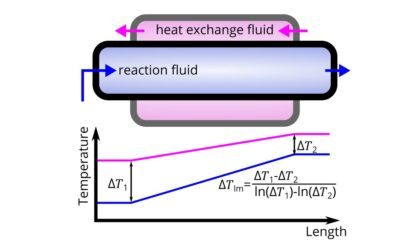

How to calculate heat transfer in continuous flow applications

Continuous flow (such as micro-reactors) are superior for exothermic reactions. How do you compute the thermal performance of a reactor?

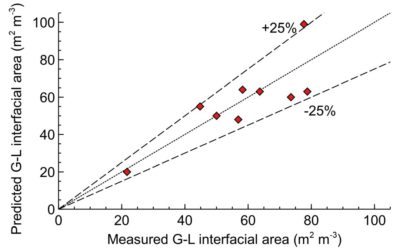

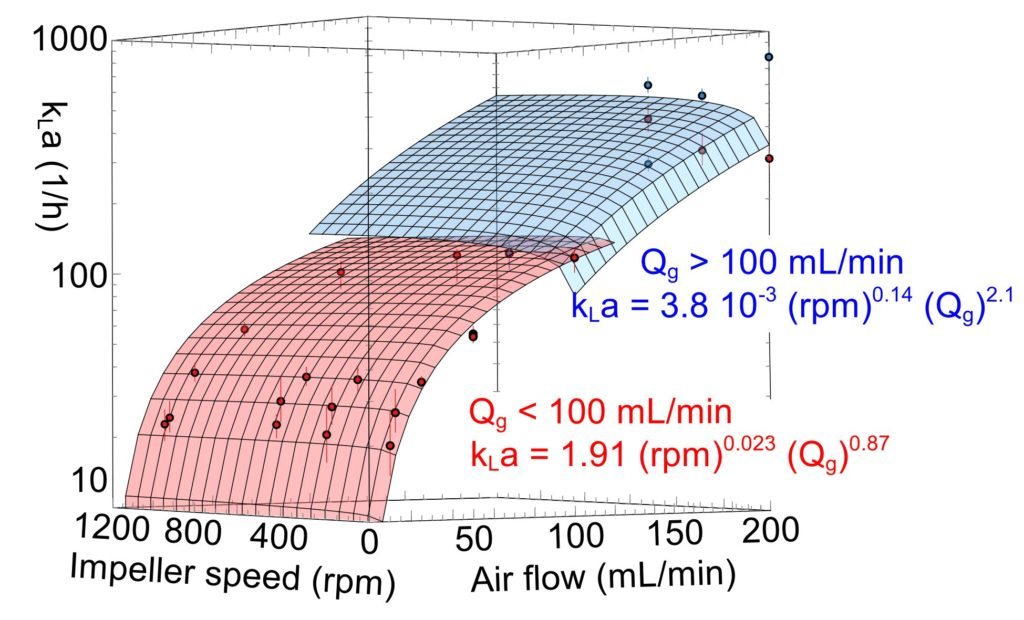

Maximising interfacial gas-liquid area with Scalable Agitated Baffle Reactor (SABRe)

How the SABRE system provides large gas-liquid area to maximise the reaction throughput and selectivity.

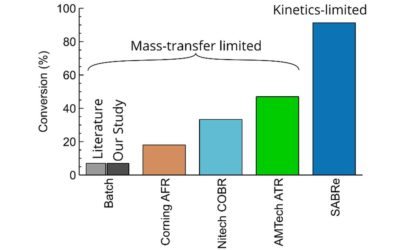

Comparison of continuous reactors in enzymatic esterification

We showed superior performance of SABRe in the enzymatic (liquid-liquid) esterification.

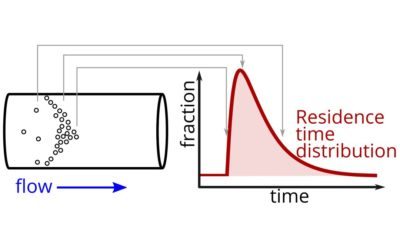

How residence time affects product quality in flow chemistry

How residence time is vital for throughput and product quality.

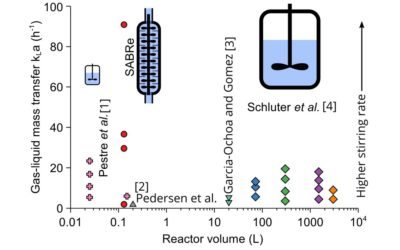

Gas-liquid mass transfer (kLa) in scalable flow chemistry. Scalable Agitated Baffle Reactor (SABRe)

The gas-liquid mass transfer coefficient is a key parameter in multiphase reactions. We studied it for the SABRe.

Residence time distribution in the Scalable Agitated Baffle Reactor (SABRe)

The SABRe provides precise residence time control.

Specifications

| Primary Wetted Material | 316 Stainless or C276 Hastelloy |

| Secondary Wetted Material | PTFE / FFKM |

| Reactor Volume | Lab: 20 – 120 mL |

Download specifications (pdf)

Specifications: size, mass, operating parameters

Lab system 100 mL

Internal volume | 20 or 120 mL with various inserts |

Temperature | -190 to 200 C |

Pressure (material dependent) | Standard: vacuum to 20 bar Bespoke: up to 100 bar |

Residence time | 30 s to 5 hr in continuous Could be use in batch-mode! |

Mixing Speed | 10 to 1500 RPM |

Dimensions | Reactor & Stand 300 x 300 x 850 mm Skid (turnkey system) 450 x 680 x 1910 mm |

Weight | Reactor & Stand 15 kg Skid 35 kg |

Connections | Swagelok 1/8” or 1/4″ in. reagent port Swagelok 1/8” or 1/4″ in. reagent port M16x1 or 12mm pipe for circulator |

Stirrer | almost any overhead stirrer, such as IKA |

Pumps | any liquid pumps such as HPLC or peristaltic |

Pilot system: 1L

Piloting starts in 2022. There are still 2 opportunities to join the piloting programme and benefit from scalable & multipurpose continuous processing.

Pilot system: 10L

Piloting in progress. There are still 2 opportunities to join the piloting programme and benefit from scalable & multipurpose continuous processing.