Comparison of common chemical reactors

We overview and compare various chemical reactor technologies and overview their performance:

- Scope (or a range of suitable processes)

- Scalability (how quickly and easily a process could be scaled-up)

- Reaction control

- Energy efficiency

- Catalyst lifetime (for heterogeneously-catalysed reactions)

It is our subjective view – please contact us if we have overlooked or misrepresented an important point.

Plug Flow (tubular reactors)

Tubular reactors (sometimes also incorrectly referred to as “plug flow”) are the simplest continuous reactors possible. It is simply a long pipe. Why not “plug flow” – because it often creates confusion with the plug flow reactor model – an ideal reactor.

Daniel Lambden overviews of the tubular reactors.

You can see that neither reactor type solves all the needs.

Multipurpose batch plants allow relatively low-capital manufacture but suffer from numerous inefficiencies. Batch has slow heat and mass transfer also limit chemistry scope – as a result, long and inefficient synthesis chains become unavoidable.

Pollak in “Fine Chemicals” writes: “The main product in small batch campaigns is cleaning”.

Flow processing addresses main inefficiencies, but flow reactors are narrow in scope and require large capital for multi-purpose production.

Combining the benefits of the batch and flow?

We have developed a patent-pending reactor design that combines the benefits of the batch and flow reactors. It is multifunctional and can handle most batch processes (hence, low capital costs); scalable into multi-ton production; and simple – most batch knowledge could be directly applied.

Would you benefit from the flow?

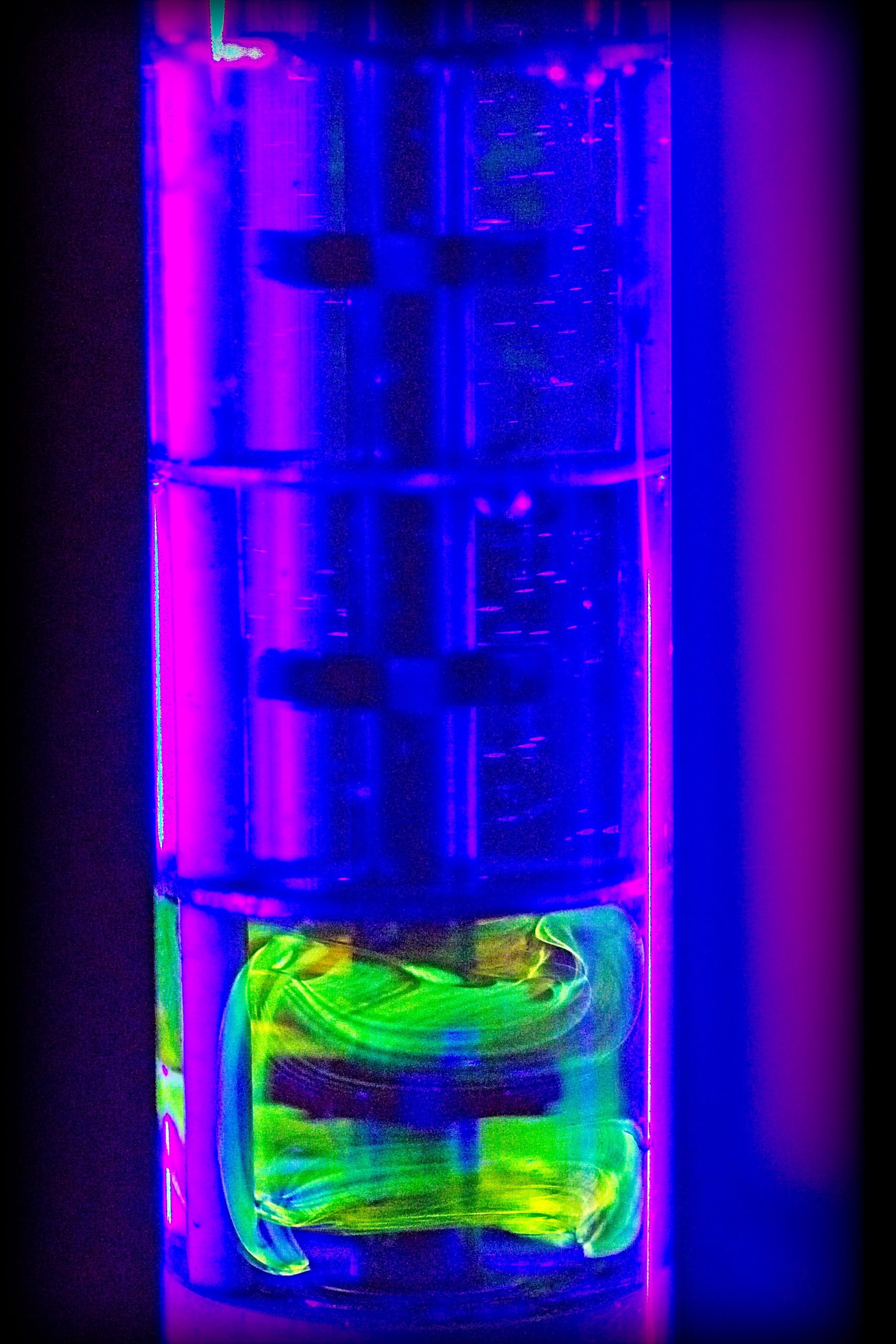

Best in class mixing performance.

See our product range and the SABRe – the reactor that can do most batch processes in flow with exceptional heat and mass transfer and lightning-fast mixing.