Problem

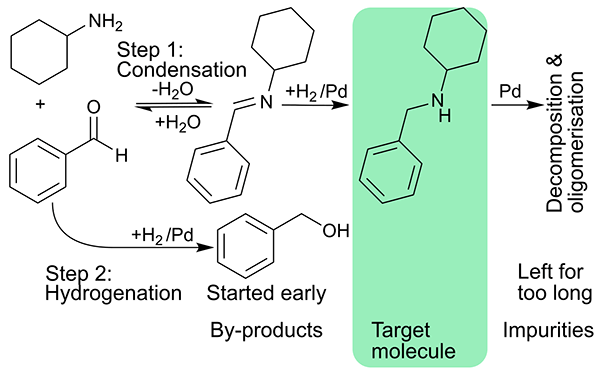

Cascading several reactions into one creates an opportunity to simplify product synthesis and reduce the number of unit-operations. In this regard, we investigated the synthesis of an imine followed by its hydrogenation into amine.

The reaction cascade requires precise control of reaction conditions:

- starting hydrogenation too early results in aldehyde hydrogenation and by-product formation.

- leaving hydrogenation for too long results in impurities such as decomposition, oligomerisation, and aromatic ring hydrogenation.

What’s the benefit?

Continuous flow chemistry provides superior heat and mass transfer. Small reactor volume enhances process safety opening new process windows (temperature, pressure) for process intensification and enables rapid optimisation of process conditions.

What did we do?

We optimised the solvent, substrate concentration, catalyst, residence time and temperature in the continuous-flow hydrogenation of an imine to an industrially relevant secondary amine used for pharma applications.

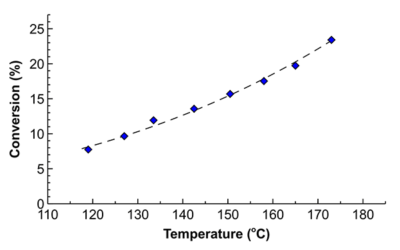

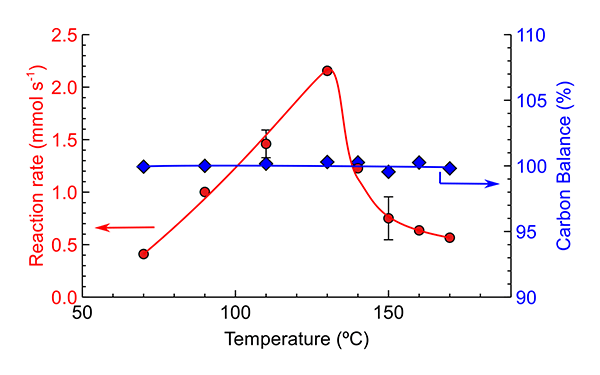

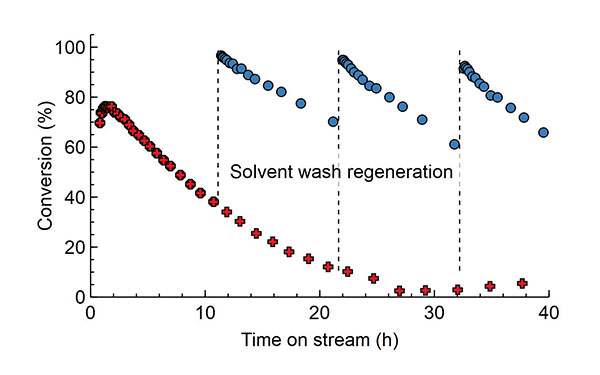

Imine reactions are known to cause rapid catalyst deactivation. This is less of an issue in batch processing where catalysts may be replaced after each cycle at high expense. In continuous flow, however, process intensification allowed for evaluation of the optimal reaction temperature (130 oC) to maximise reaction rates while minimising catalyst deactivation.

Continuous flow reactors allow for catalyst utilisation – by a factor of 10-1,000x higher compared to batch.

Outcome

Rapid process development in continuous flow allowed us to develop a detailed process understanding of the imine hydrogenation process including reaction and deactivation rates. We quickly established the optimum solvent (THF) and reaction temperature to maximise the desired product yield and minimise impurity formation. Data are published in the Industrial & Engineering Chemistry Research journal.

Scheme of cascaded imine synthesis and hydrogenation

Imine hydrogenation rate and total carbon balance as a function of temperature

Time on stream imine conversion without and with solvent washing regeneration (dashed vertical lines)

Catalyst for fuel cell applications

We have developed a monolith-based fuel cell catalyst for sustainable remote energy generation.

Process intensification in hydrogenation

Short residence time and high temperature – an impossible combination for batch – allowed increasing specific reaction rates 8-fold in flow with the same product quality.