Problem

A leading European research institution required manufacturing 10 kg of bespoke catalyst for a pilot test. The catalyst preparation procedure was based on a 10 g laboratory-scale process that required developing a scale-up approach.

Is the 10 kilo scale a problem?

Bespoke catalysts on a multi-kilogram scale are usually impossible to procure from major suppliers due to:

(i) 10 kilo scale is too small for commercial production, and

(ii) the catalyst preparation recipe is often not directly scalable.

Stoli offered a service to develop a scale-up procedure, validate that the catalyst meets specifications, and manufacture the required catalyst amount.

What did we do?

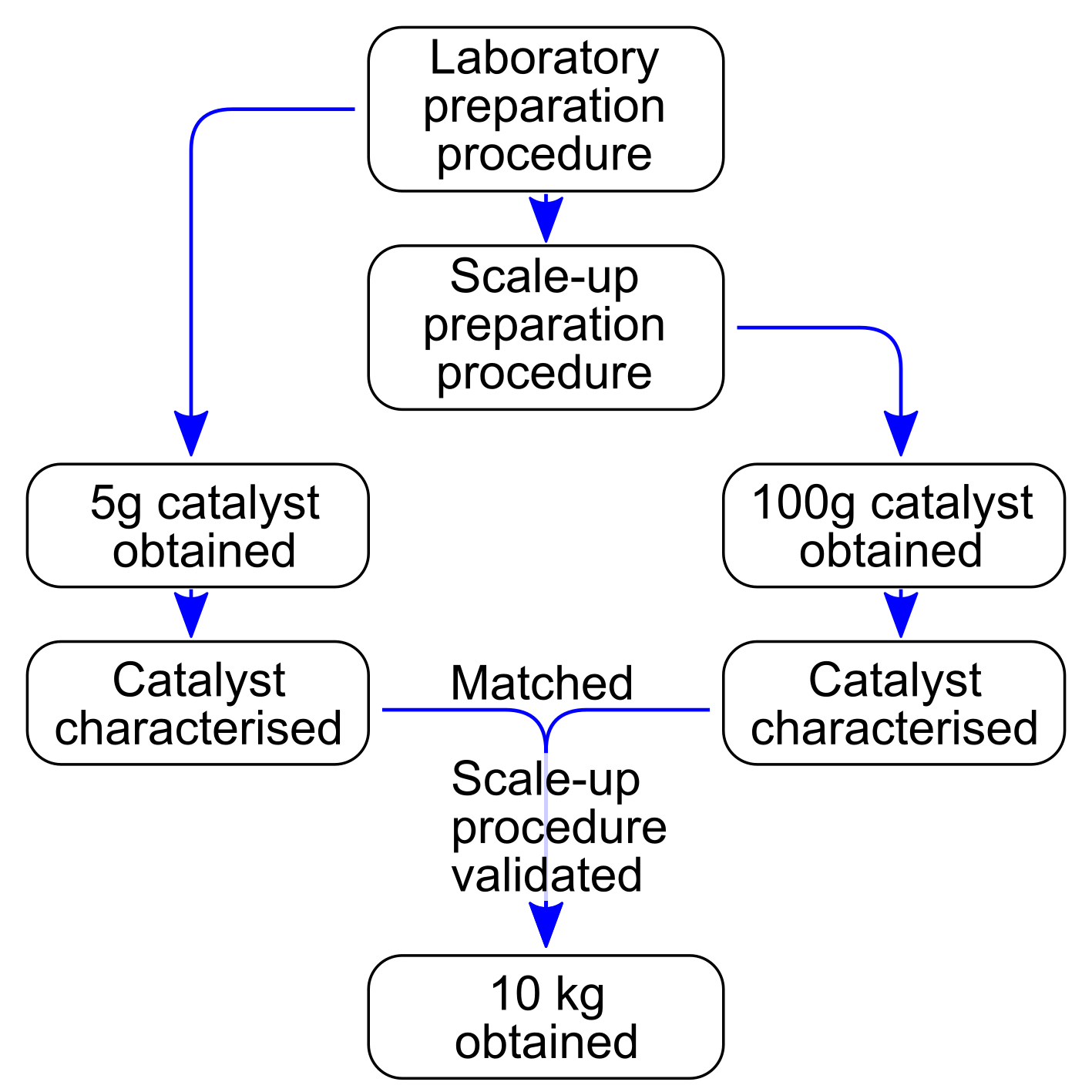

Firstly, we adapted the lab-scale catalyst preparation procedure for the large-scale manufacture. We obtained samples of catalysts using both procedures.

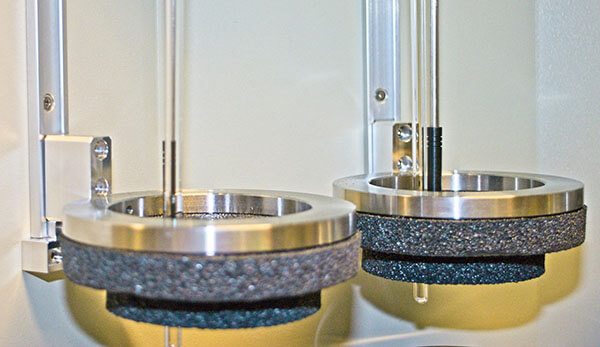

A detailed characterisation of the lab-scale recipe and a small amount catalyst produced with the kilo-scale recipe confirmed identical characteristics.

Once the scaled-up manufacturing procedure had been validated with characterisation, we rapidly prepared 10 kg of catalyst.

Outcome

Stoli met the customer requirements and shipped the catalyst to the customer within weeks. The catalyst was successfully demonstrated in a biofuel production process.

The catalyst recipe and method developed by Stoli could be used directly for commercial-scale production.

Scheme of catalyst scale-up procedure development and validation

BET surface area and porosity analysis as one of characterisations performed

Scaled-up catalyst extrudate

Catalyst for fuel cell applications

We have developed a monolith-based fuel cell catalyst for sustainable remote energy generation.

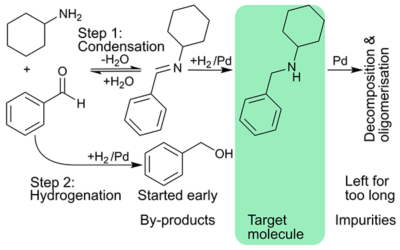

Cascading imine formation and hydrogenation

Stoli cascaded imine formation and hydrogenation; intensified process to maximise rate, and catalyst utilisation.

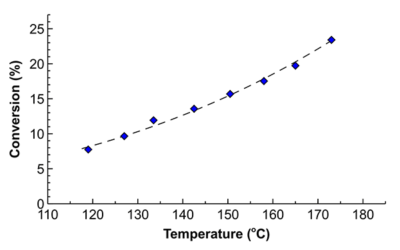

Process intensification in hydrogenation

Short residence time and high temperature – an impossible combination for batch – allowed increasing specific reaction rates 8-fold in flow with the same product quality.