Enzymes are nature’s bio-catalysts and are used in multiple industries as a low-cost route to many chemical intermediates.

Why enzymatic chemistry is on the rise?

Enzymes can activate complex chemical transformations without the need for precious metals and under mild reaction conditions with excellent product selectivity and yield. Therefore, enzymes are a sustainable alternative to traditional synthetic chemistry.

Download pdf

Case Study # 06, rev 7,

13 Sep 2021, By Daniel Lambden

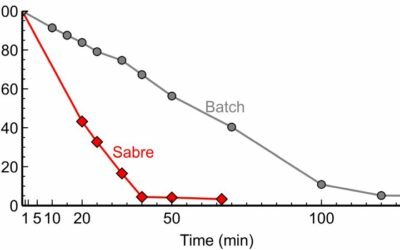

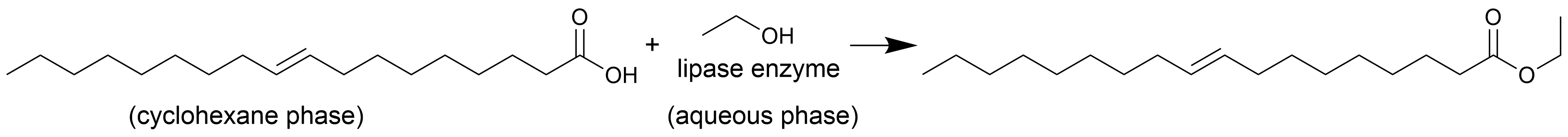

Ezymatic esterification of oleic acid with ethanol is used as a model reaction for reactor comparison. The reaction rate is often limited by the interphase mass transfer. Performing the same reaction under the same conditions provides an excellent comparison for various reactors.

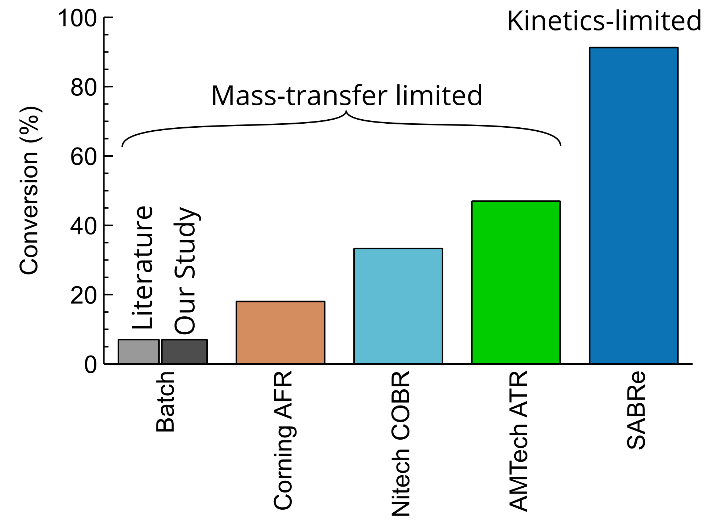

Performance of many reactors under the same conditions are published. The reactors include a batch reactor, several plate reactors based on static mixers (such as Corning AFR), and several actively-agitated reactors such as NiTech’s COBR and AM Technology’s ATR [1-2]. Not surprisingly, actively agitated reactors outperformed static mixers generating additional interfacial area and higher conversion. The best continuous reactor outperformed batch manufacturing by 6-fold! Due to the SABRe’s high agitation and mixing capabilities, we were interested to see how our reactor performed.

Experimental procedure

A comparison study with the literature requires exactly the same conditions and making reference comparisons. We contacted the authors of the research paper [1] and clarified reaction conditions to replicate the experiment. This agreement confirmed validity of the test procedure and the reactor comparison.

Once the validity was confirmed, we studied the SABRe performance combining two solutions: (i) 0.1M oleic acid in cyclohexane, and (ii) 0.3M ethanol, 5000 LU/g candida antarctica lipozyme in pH 7.2 phosphate buffer solution. Both solutions were pumped with HPLC pumps to give a mean residence time of 2.3 min at the process temperature of 30 ± 0.5 C into the SABRe reactor operating at several stirring rates. The products were collected after 3, 5, and 11 reactor volumes.

Results for the Scalable Agitated Baffle Reactor (SABRe)

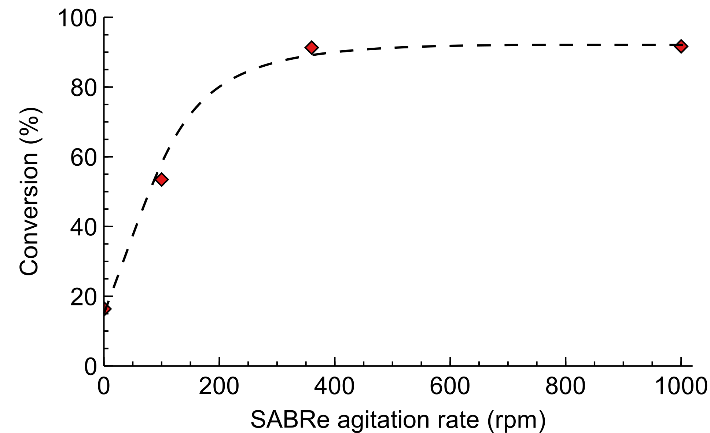

Ester conversion significantly increased with the stirring rate. Faster agitation in the reactor increased interfacial mass transfer and the conversion in the reaction. The conversion was similar at 360 rpm and 1000 rpm indicating that the reaction rate is limited by intrinsic kinetics at higher RPM. The SABRe provided rapid mass transfer and exceeded the intrinsic rate of this enzymatic reaction.

Comparing Various Reactors

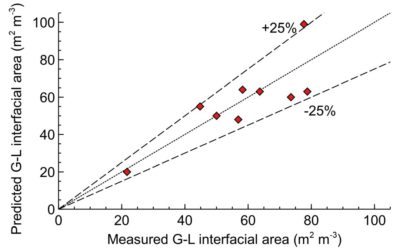

The stirring rate data indicates high performance of SABRe, especially in mass-transfer limited processes.

Without further optimisation, the conversion observed in SABRe was above 91% at the mean residence time of 2.3 minutes. This conversion was twice that of the next highest performer!

This high conversion comes from SABRe’s efficient mixing. The design of the reactor provides excellent mixing characteristics, precise control of residence time and a clear route to scale up.

The comparison was performed at a mixing energy of only 0.5 W/L which could be maintained in reactors above 5,000L [3] meaning the same exceptional SABRe performance can be scaled from lab to production. This will enable the manufacturer to increase the yield, throughput and quality of material produced with only a small modification to their process!

References: [1] E. Sebastien, Chimica Oggi – Chemistry Today – vol. 31(6) November/December 2013, p43-46; [2] Chimica Oggi – Chemistry Today – vol. 32(4) July/August 2014, p4-5; [3] V. Schlüter, W.D. Deckwer, Chem. Eng. Sci. 47 (1992) 2357–2362.

The SABRe system provides the highest performance in class in interfacial mixing for more efficient, faster, and precise chemical production.

The SABRe system (available in steel, Hastelloy or glass) is suitable for a wide range of chemical applications. Combining simplicity with superb reaction control, SABRe is the best choice for simple, safe and cost effective chemistry.

What can the SABRe do for you today? Get in touch and arrange a trial.

Other SABRe case studies:

Improvement of enzymatic oxidation in the continuous Scalable Agitated Baffle Reactor (SABRe) system

Case study on enzymatic oxidation by Prof John Woodley

Steven’s oxidation with Vapourtec

1.4 kg/day multiphase oxidation obtained integrating SABRe system with Vapourtec’s R-Series

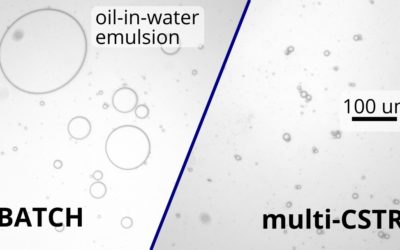

Consistent oil-in-water emulsions in continuous flow

Using a continuous multi-CSTR system allowed us to make droplets 2.5 times more uniform compared to a batch reactor

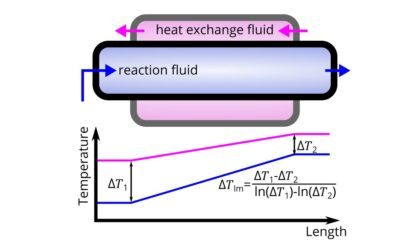

How to calculate heat transfer in continuous flow applications

Continuous flow (such as micro-reactors) are superior for exothermic reactions. How do you compute the thermal performance of a reactor?

Maximising interfacial gas-liquid area with Scalable Agitated Baffle Reactor (SABRe)

How the SABRE system provides large gas-liquid area to maximise the reaction throughput and selectivity.

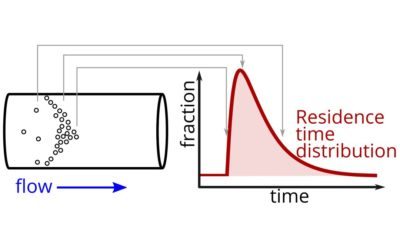

How residence time affects product quality in flow chemistry

How residence time is vital for throughput and product quality.